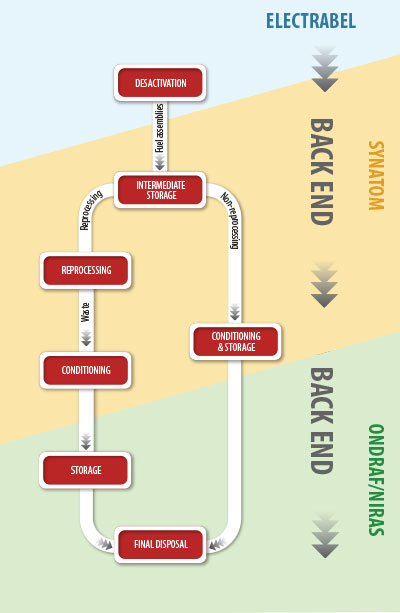

Back end of the nuclear fuel cycle

The back end of the nuclear fuel cycle involves managing the spent fuel after irradiation. For Synatom, this entails all the steps between draining the nuclear units' spent fuel pools and final storage.

Period in the spent fuel pool

When unloaded from reactors for the final time, assemblies continue to emit a large amount of radiation and a lot of heat. They are stored underwater in water containing boron, in a spent fuel pool. The water has a dual function, acting as both a radiation shield and a cooling element. The period of three to five years spent in this pool:

- reduces the radioactivity of the short-lived fission products;

-

evacuates some of the residual heat.

Once the period for which the spent fuel assemblies need to be kept in the spent fuel pool is over, Synatom again takes over full responsibility for managing these assemblies.

Did you know…

When unloaded for the final time, spent fuel assemblies still emit 2,000 kW of power. At the end of their time in the spent fuel pool, this will be below 10 kW.

Interim storage

In 1993, the Belgian Government decided to establish a moratorium on reprocessing spent fuel assemblies. As a result, the assemblies must be stored on the nuclear power plant sites. To avoid the spent fuel pools becoming saturated, two interim storage buildings were constructed: one at Doel and the other at Tihange.

Synatom developed two approaches:

-

Dry storage in special containers at Doel. The Fuel Container Unit building (SCG, standing for Splijtstof Container Gebouw in Dutch) was commissioned in 1995 and was designed to house 165 containers, each of them holding between 24 and 37 assemblies. On average, five additional containers a year are brought to this storage building. Synatom owns all the dry storage containers at Doel and, with the aid of TRACTEBEL Engie, coordinates all operations associated with market research, licensing, orders and container production monitoring. Synatom draws up long-term delivery schedules to ensure that they are always available in good time for the operator.

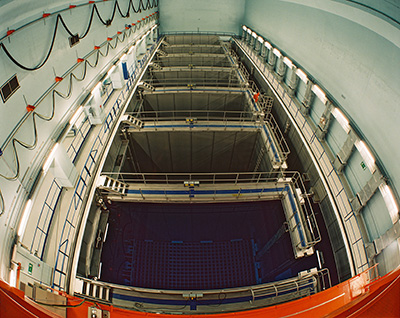

Tihange: underwater interim central storage building

-

Underwater storage in a central building at Tihange. At Tihange, a special building, called "DE", was commissioned in 1997. It contains eight pools that can hold a total of 3,720 assemblies, which are stored in racks covered by boron water 8 metres deep.

Synatom has made the financial resources available to construct the central storage building. Given the active life of the nuclear units, new interim storage capacities will need to be established at both Doel and Tihange in the next few years.

How do transfers take place?

At Doel, spent fuel assemblies are placed directly in the container that is going to provide them with dry interim storage. This step takes place in the spent fuel pool.

Once a container has been filled, it is dried and closed and then put on a trailer to be taken to the central building holding the containers from the four units.

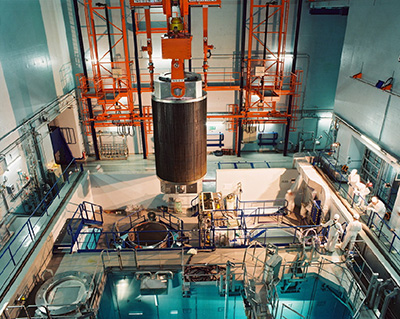

Container in spent fuel pool at Doel 4

At Tihange, assemblies are placed in a shuttle container for transfer between the respective unit's spent fuel pool and the central underwater storage building. When the container, which can accommodate 12 assemblies, arrives at the storage building, it is opened and the assemblies are put in an underwater pool. The container is then repackaged in preparation for another transfer. Electrabel takes care of the various handling operations on behalf of Synatom.

Tihange: the transfer container arriving at the interim central storage building

Synatom owns the transfer container at Tihange. The specifications and safety dossier relating to the purchase of a second shuttle were finalised in 2015. If everything goes according to plan, this shuttle should be operational by the early 2020s.

In summary, Synatom sees to all the costs of managing the spent fuel assemblies on the Doel and Tihange sites.

What lies in store for these assemblies in the years ahead?

The moratorium on reprocessing decided on in 1993 still applies today. The overall evaluation of the two options (reprocessing and no reprocessing) has not yet been completed. In this light, interim storage is sure to continue for a number of decades yet on the Doel and Tihange sites – a situation forcing Synatom to plan additional storage capacities on each of the two sites, meaning that Synatom will be required to go on submitting the relevant safety reports to the supervisory authorities the Federal Agency for Nuclear Control (AFCN/FANC) and Bel V.

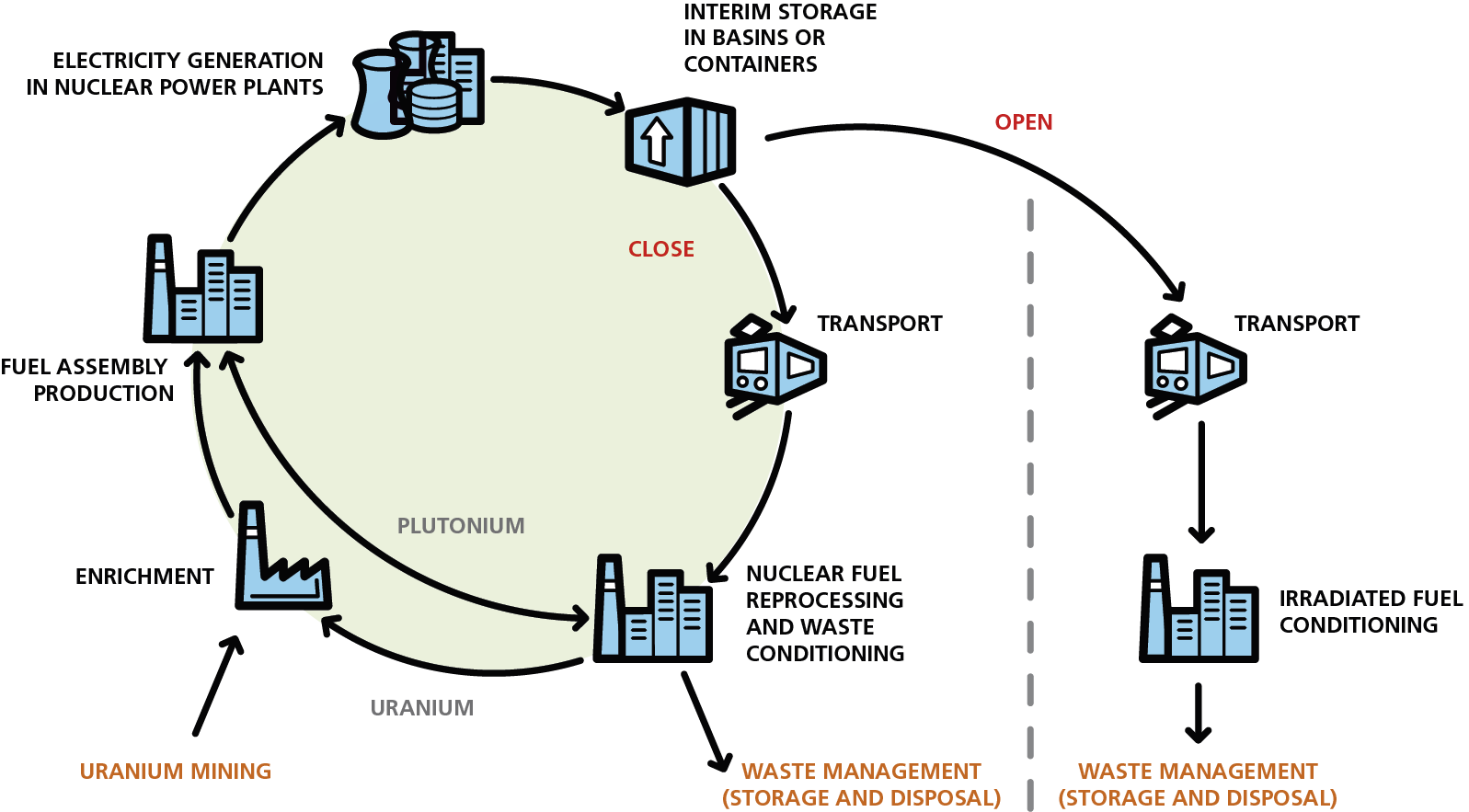

In the meantime the Belgian authorities will have to make a choice between open cycle (no reprocessing) and closed cycle (reprocessing).

What is the difference between an open cycle and a closed cycle?

A cycle is referred to as "closed" when the spent fuel assemblies are reprocessed. The reprocessing separates the uranium, the plutonium and the fission products. The uranium and plutonium can be reused to produce new fuels. The fission products are vitrified and the structural components are compressed. This waste is stored in anticipation of its final conditioning and disposal.

A cycle is said to be "open" when there is no reprocessing. In this case, the whole of each spent fuel assembly is regarded as waste. The assemblies are stored with a view to reducing their temperature and radioactivity levels. They are then conditioned before final disposal. Please note that the open cycle involves volumes of waste (to be stored) that are substantially greater than for the closed cycle.

Regardless of the choice that is made, ONDRAF/NIRAS takes care of the spent fuel assemblies or the waste arising from their reprocessing.

To this end, ONDRAF/NIRAS and its subsidiary Belgoprocess need to have interim storage facilities pending a final storage solution.

A brief history

In the late 1970s, Synatom signed a number of reprocessing contracts. In total, 670 tonnes of spent fuels from the Doel 1, Doel 2 and Tihange 1 nuclear reactors were reprocessed at the Areva plant in La Hague in France.

In 1993, the Belgian Government imposed a moratorium on reprocessing. This moratorium still applies today.

And finally …

Once the reprocessed assemblies and reusable materials (which account for 96% of all the materials) have been recovered, all that remains to do is to ensure the safe management of the final waste.

There are two categories of waste:

-

non-reusable materials (high- and medium-level radioactive waste with a long half-life): these are vitrified;

-

structural components of assemblies (medium-level radioactive waste with a long half-life): these are compressed.

Belgian wastes after reprocessing

Mol railway station: transshipment of a waste container following reprocessing of the spent fuel

The situation in late 2015

-

All vitrified high-level radioactive waste is stored at Belgoprocess in Dessel.

-

All compressed medium-level radioactive waste has also returned to Belgoprocess.

-

Vitrified medium-level radioactive waste is still expected to return to Belgium.

Belgoprocess in Dessel: upper level of the storage building for vitrified waste

Synatom's responsibilities

Synatom works in close cooperation with NIRAS-ONDRAF to draw up technical specifications for the conditioning and characterisation of waste. An independent expert's report is compiled at the La Hague reprocessing plant to ensure Areva's strict compliance with Belgian requirements.

The company has, since 2000, taken charge of returning waste containers.

The final consignments are planned in 2017.

Synatom pays NIRAS-ONDRAF a fee to store the waste from reprocessing.

It establishes provisions for financing all the activities associated with the management and final storage of this waste.

Research and Development

For many years now, Synatom has provided NIRAS-ONDRAF with substantial financial support for Research and Development with a view to coming up with acceptable solutions for storing medium- and high-level nuclear waste underground. For the period from 2015 to 2020, €130 million have been made available to NIRAS-ONDRAF to pursue its work on storage in deep geological repositories, and specifically in Boom clay.